High Quality Automatic Roll Slitting Machine Exporters – YWFQ1300a Model Vertical Type 200m/Min Slitting Rewinding Machine for Plastic Film and Paper – JINYI

High Quality Automatic Roll Slitting Machine Exporters – YWFQ1300a Model Vertical Type 200m/Min Slitting Rewinding Machine for Plastic Film and Paper – JINYI

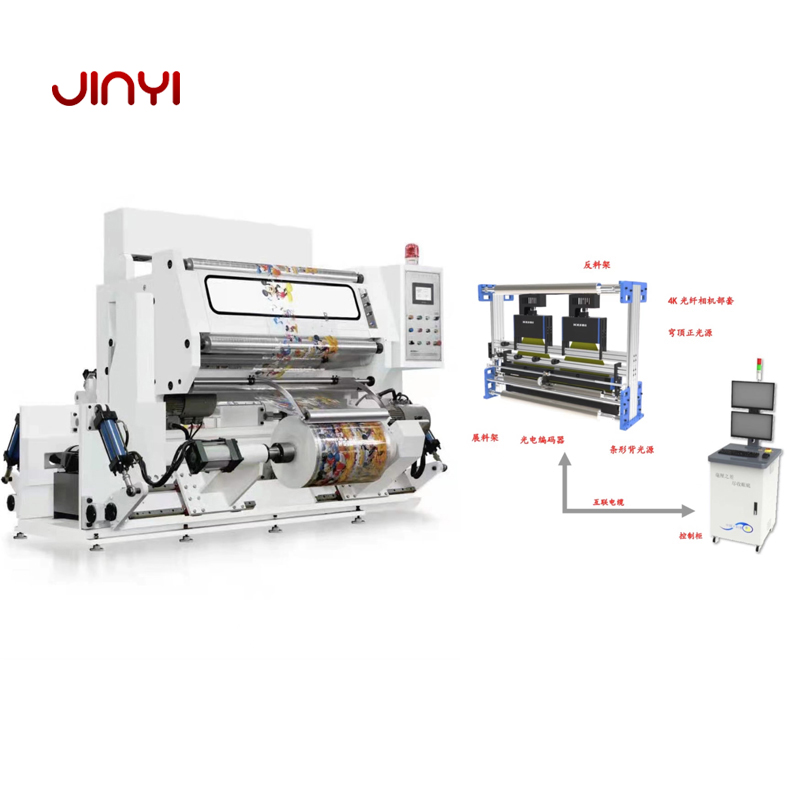

High Quality Automatic Roll Slitting Machine Exporters – YWFQ1300a Model Vertical Type 200m/Min Slitting Rewinding Machine for Plastic Film and Paper – JINYI Detail:

Technical specification

|

Model |

YWFQ1300(Width can be made to 2600mm) |

|

Width |

1300mm |

|

Unwind diameter |

600mm(Can make to 1200mm) |

|

Rewind diameter |

500mm |

|

Paper core diameter |

3 inch or 6 inch |

|

Slitting speed |

200m/min |

|

Slitting width |

30-1300mm |

|

Slitting precision |

0.5mm |

|

Power |

5KW |

|

Weight |

1600KG |

|

Dimension |

1520*2580*1450mm |

Feature

1. Unwind air shaft is controlled by magnetic powder brake

2. Two rewind air shafts is controlled by two brake clutch

3. Whole machine is PLC control, unwind and rewind tension is automatically controlled

4. Unwind EPC device to prevent the material moving left or right

5. Main motor is inverter motor

6. It is equipped with flat blade for slitting plastic film, rotary blade for slitting paper,non woven.

7. The machine is installed with a blower to blow the waste edge away.

8. Rewind pressing roller make rewinding roll more even and neat.

Use

This machine is used to slitting and rewinding all kinds of roll materials such as BOPP, PET, CPP ,PE,PVC ,POF ,PAPER etc .

parameters

Main parameter

1. Max. width of slitting material: 1300mm

2. Min. width of slitting material: 25mm

3. Max. slitting speed: 200m/min.

4. Max. unwind diameter:600mm

5. Max rewind diameter: 500mm.

6. Paper core diameter:76mm or 152mm

7. Machine power: Max 5kw

8. Overall dimension: 1520*2580*1450mm

9. Net weight: 1.6T

Unwind unit

1. Unwinding adopts magnetic brake (50N.M)

2. Unwinding adopts air shaft

3. Automatic tension control

4.Web guide precision: ±0.5mm

5. Web guide mode: Edge guide and line guide

Traction part

1. Pneumatic pressing roller(Φ110mm PU Material)

2. Traction roller(Φ112mm) is driven by frequency motor(4kw), transmitted by timing belt.

3. Meter-counter can count the length of film accurately.

Unwind unit

1.Equipped with flat blade (slitting plastic film)+Rotary blade (slitting paper).

2.Equipped with ruler on the cutter pole which is convenient for cutter matching

Rewind part

1.Rewinding adopts magnetic brake (50N.M), air shaft.

2.Pressing rollers, two for each rewinding shaft

3.Waste edge trim device, AC motor, 0.75KW

Frame

1. Solid cast iron base and wall board

2. Each guiding roller(ф100) has antislipping tape.

3. Unwinding, rewinding and controlling system in the same side

4.Adopt PLC centralized control,Compact structure ,easy operation ,

more longlife to use and slitting more stable

Spare parts list

|

Name and description |

Quantity |

Notice |

|

Operational manual |

1 piece |

|

|

Hex Socket Spanner |

1 set |

|

|

8 Straight Screwdriver |

1 piece |

|

|

17~19 open spanner |

1 piece |

|

|

17~19 box spanner |

1 piece |

|

|

Flat blade Holder

|

8sets |

Product detail pictures:

Related Product Guide:

What Should Be Paid Attention When Using The Slitting Machine?

Every single member from our large efficiency profits team values customers' requirements and organization communication for High Quality Automatic Roll Slitting Machine Exporters – YWFQ1300a Model Vertical Type 200m/Min Slitting Rewinding Machine for Plastic Film and Paper – JINYI , The product will supply to all over the world, such as: Porto, Serbia, Miami, We insist on the principle of "Credit being primary, Customers being the king and Quality being the best", we are looking forward to the mutual cooperation with all friends at home and abroad and we will create a bright future of business.

We have been engaged in this industry for many years, we appreciate the work attitude and production capacity of the company, this is a reputable and professional manufacturer.